Manufacturing Growth Strategy Planning: A Step-By-Step Guide to Success

When properly identified and diligently managed, capacity and utilization are the North Star for navigating a strategic growth plan. If these two elements are not fully understood, operations and supply chain planning efforts will falter. Likewise, the potential for growth through expansions, renovations or a new facility build can also be compromised.

Companies that adhere to best practices for standardized and improved production processes will avoid costly mistakes and better support their organization’s strategic growth objectives.

The Importance of Due Diligence

When measured, planned, and successfully controlled, proper capacity and utilization measures can safeguard an organization’s manufacturing growth. Without a comprehensive understanding of the current state of the organization’s existing production processes and interconnectivity, the opposite is true.

Manufacturers commonly overspend on capital investment by proceeding with facility expansions or new facility construction before they conduct a thorough due diligence assessment. They attempt to safeguard the business by ordering excess inventory instead of properly right sizing their inventory and operations.

This practice is intensified during periods of increased supply chain turmoil or global financial instability.

Growth Planning: The DMAIC Approach

Define, measure, analyze, improve and control is a data-driven strategy for improving processes that is commonly used by lean manufacturing and operations research professionals.

DMAIC provides a methodical approach to developing strategic insight and assists manufacturers that are looking to standardize or improve their production processes, redesign existing facilities, construct new facilities and/or enhance their organizations.

- Define the current state of the organization by assessing the base level of manufacturing sophistication that currently exists in your facilities. Then, define the desired growth to achieve the organization’s optimal future.

Does the facility have the appropriate equipment, budget, layout, inventory strategy, and other necessary operational tools required to meet the growth target?

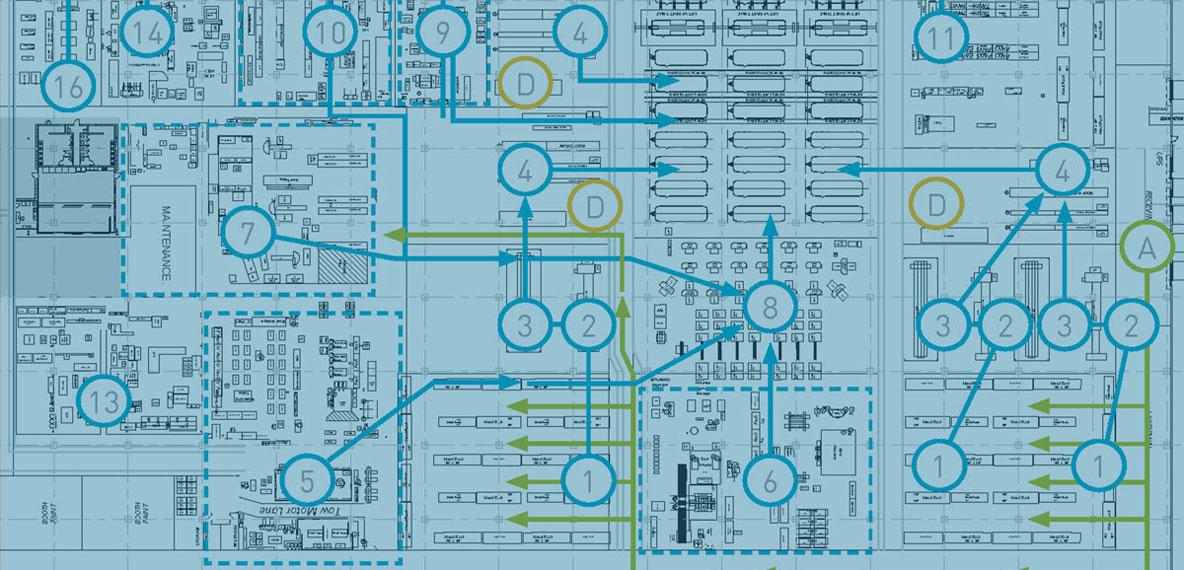

Is the facility’s layout conducive to effective manufacturing, with safety, quality, delivery, and cost in mind?

- Measure the facility’s performance by conducting a thorough operational assessment. This assessment may involve motion time studies, capacity planning, production scheduling (MRP), inventory strategies for raw materials, work in process (WIP), finished goods, sales order history, shipment/delivery history and engineering routing accuracy.

- Analyze the production processes for opportunities, such as process cycle times, inventory management strategies, and traceability of all products throughout the facility. More importantly, review the critical factors of production processes, with a gap assessment on capacity and utilization.

Ascertain whether the facility’s footprint is optimally balanced; i.e., being used effectively and efficiently to achieve the defined criteria for success. Identify OFIs for inventory reduction to clear facility space, allowing for equipment repositioning and further streamlining production labor within the process flow.

- Improve process performance by evaluating best cases for implementing growth strategies. Right-size the organization’s inventory and production instead of ordering excess inventory. Rather than expanding into a new facility immediately, enhance the existing facility footprint and use this information as a starting point for an informed design in the future.

Once the facility has been right sized to an acceptable level, then engage with architectural, engineering and construction (AEC) professional services to assist in capacity master planning, growth modeling, facility utilization planning and, if applicable, facility expansion or new facility site selection.

- Control the improved manufacturing process and stabilize growth with proper master- planning efforts. Create key performance indicators (KPIs) to track improvements. Recognize, however, if the KPI tracking systems are not driving productive responses, they may not be the right KPIs. Create stop gaps and visual cues to determine when inventory is becoming unmanageable or overstocked and readjust inventory replenishment levels as necessary. Continue to monitor the existing footprint and always seek to identify and eliminate any bottlenecks as they appear.

Data-driven strategies help manufacturers make informed decisions to streamline and improve processes.

Without a complete understanding of real-time capacity and utilization, leadership will continue to operate in the rear-view and default to “the way it has always been,” often carrying the inefficiencies of its existing production practice into its future growth strategy. This behavior results in a ballooning backlog of production orders that will continue to increase if the proper due diligence is not performed.

Without properly identifying the root cause, manufacturers in many cases can become increasingly unable to fulfill their customer orders and frantically chase a backlogged pipeline, attempting to remedy the situation. Temporary solutions can lead to hasty decisions involving increased capital assets, short-term facility expansion efforts and construction of additional manufacturing facilities.

If the company had performed proper due diligence in the beginning, it may have better utilized its facility’s square-footage to remove bottlenecks from production processes.

This article was originally published by IndustryWeek

Content Type

Published Articles

Date

March 08, 2023

Market

Topic

Manufacturing Equipment