Siemens Opens State-of-the-Art Manufacturing Facilities in California and Texas

Siemens celebrated two monumental milestones in March with the grand openings of its cutting-edge manufacturing facilities in Pomona, CA, and Fort Worth, TX. These new hubs will bolster Siemens' capacity to meet the growing demand from critical sectors such as the commercial, industrial, and construction markets while powering AI data centers all over the country.

Pomona, CA, Facility:

Siemens’ new 150,000-SF greenfield facility in Pomona will allow the factory to increase production of vital low-voltage electrical equipment such as switchboards and lighting panels.

The completion of this facility marks the first phase of a $95 million expansion plan, which will be followed by the remaining 50,000 SF of Phase 2 construction. Once complete, the new manufacturing hub will be three times larger than the original site.

The Pomona facility sets a new standard for sustainable construction in the region. Designed to be carbon neutral, it is on track to become the first LEED Gold-certified industrial building in the city. The facility will feature cutting-edge sustainable features, including a rooftop photovoltaic system to generate renewable energy, advanced water and energy metering, and a community space that will showcase local art.

Fort Worth, TX, Facility:

Siemens' 500,000-SF electrical equipment manufacturing plant in Fort Worth plays a crucial role in producing low-voltage switchboards and electrical components needed to meet the soaring demand from America’s AI growth.

Meeting Siemens’ goal to maintain assets that are net-zero carbon in operation by 2030, the Fort Worth facility is carbon-neutral and is setting the standard for sustainable manufacturing. Featuring an all-electric powder coating system, electric forklifts, low-energy-consuming HVAC systems, photovoltaic streetlights, advanced energy monitoring, and Breakthrough Energy-backed energy-efficient LuxWall windows, the Fort Worth facility is an archetype for the future of manufacturing—lowering cost and energy usage wherever possible.

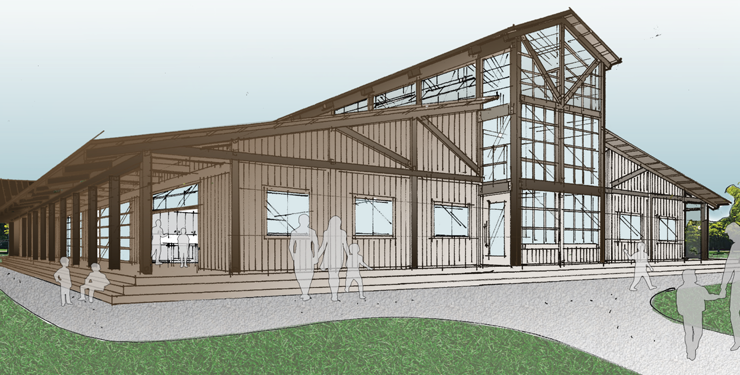

BHDP’s Involvement

BHDP is proud to lead the architectural design for both of these transformative projects.

Dustin Weida, Senior Architect at BHDP, shared: “We’re excited to contribute to the development of facilities that not only support critical industries but also set a new benchmark in sustainability. We’ve worked diligently to design spaces that will not only meet today’s demand but also be flexible enough to support future growth and technological advancements.”

See additional news coverage on Manufacturing Dive, Plant Services, and AP News.

Author