Designing Best-in-Class Operations That Achieve Breakthrough Productivity, Cost, and Speed-to-Market Goals

BHDP Architecture began as an industrial design firm in 1937, with Cincinnati Milacron as our first client. While we have diversified into several markets since then, we are incredibly proud of our industrial design heritage and continue to strive to utilize our unique design process and technologies to strategically plan and design manufacturing facilities, warehouses, and distribution centers around the world, having completed projects in over 25 countries on six continents.

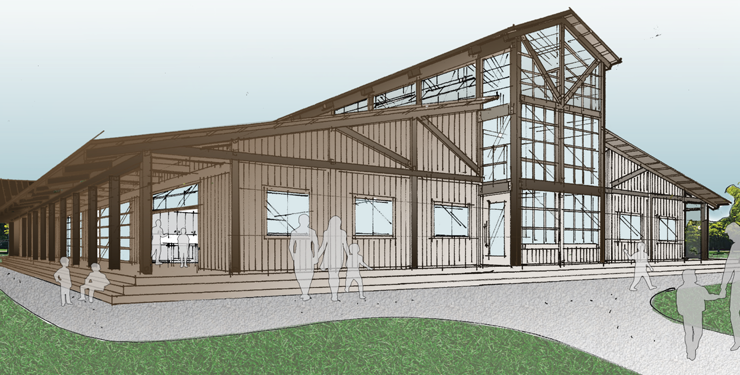

With effective client engagement throughout a project, we establish a shared understanding of key business drivers, operational requirements, and organizational culture objectives. Our integrated design process ensures the interaction of people, operational work processes, and functional space are harmonized to create innovative design solutions that bring our client’s goals to life.

If VEGA was ever going to do another expansion … it’s a no-brainer that we would use BHDP for architectural design. They understand the values of our business, and to me, that is difficult to find in the modern world.

John Groom, President, VEGA Americas, Inc

Our People